The Directorate of Research is headed by the Director of Research who is assisted by 4 Additional Directors of Research in the areas of Crop Improvement; Natural Resource and Plant Health Management, Horticulture and Food Science, Farm Machanization and Bioenergy; Associate Director of Research, Director Seeds apart from Directors/Incharges of the Research Stations/Seed Farms.

Keeping in view the existing and emerging problems in agriculture so as to find out their viable solutions, PAU carries out research in agriculture and allied disciplines including basic sciences and humanities, farm engineering and home science.

| Variety | Optimum sowing time | Seedling age at transplanting | Average yield (q/acre) | Days to maturity (after transplanting) | Resistance to bacterial blight pathotypes | Important remarks |

| PR 132 | May 20-25 | 30-35 days | 31.5 | 111 | Apply 25% less urea than other varieties (i.e. 1.5 bag urea per acre) | |

| PR 131 | 31.0 | 110 | 10/10 | Avoid sowing in sub-mountainous areas | ||

| PR 129 | 30.0 | 108 | 10/10 | |||

| PR 128 | 30.5 | 111 | 10/10 | |||

| PR 122 | 31.5 | 117 | 10/10 | |||

| PR 121 | 30.5 | 110 | 10/10 | |||

| PR 114 | 27.5 | 115 | 5/10 | |||

| PR 113 | 28.0 | 112 | 8/10 | Coarse rice variety | ||

| PR 130 | May 25-31 | 30.0 | 105 | 10/10 | ||

| HKR 47 | 29.5 | 104 | 0/10 | Suitable for parboiled rice | ||

| PR 127 | 30.0 | 107 | 10/10 | Do not grow in poor quality irrigation water | ||

| PR 126 | May 25- June 20 | 25-30 days | 30.0 | 93 | 7/10 | -Complete urea application up to 35 days of transplanting -Do not transplant after 15th July |

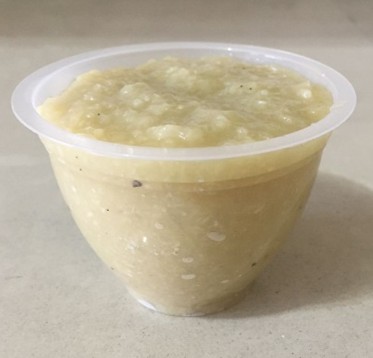

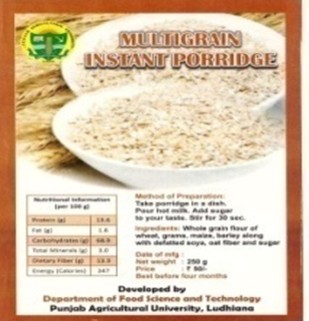

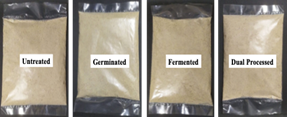

1. The Department of Food Science and Technology has developed numerous post-harvest technologies for valorization of agricultural produce. These include Sugarcane Juice Bottling Technology and sugarcane juice kheer. Several multigrain flour mixes such as multigrain atta, gluten free atta and multigrain flour for diabetics have been developed. Potato-based products such as Aloo wadi, Samosa/parantha potato premix, Aloo bhujia, Aloo chakli, Aloo papad, ready to cook non-cereal pudding mix and soup mix, ready-to fry frozen potato shammi kebab have been developed. Technologies for extruded products such as variety pasta, snacks and instant porridge has been standardized. Bio-processed millet flour and premixes, millet based extruded, baked and indigenous products have been developed. Besides, high protein soy powders for beverage and food applications are available. Technologies for instant wheat noodles and Infused honey have been recommended. Value added products from turmeric -turmeric pickle and turmeric incorporated pasta, cookies, muffins and pizza base have been standardized. Several other products including value-added products from figs and kinnow such as kinnow fruit bar and kinnow burfi have been developed. Recent notable achievements include valorized products (smoothie, powders, preseves) from jamun, dates, guava, garlic and dragon fruit. Other notable technologies include fermented baby corn pickle, probiotic kulfi. By use of non-thermal processing methods, modified millet flours and cereal starches have been developed for diversified food uses. Prebiotic dairy analogues from field pea, dal analogues, meat analogues have also been developed and characterized.

2. Department of Processing and Food Engineering: Agro-Processing Complex (APC) and Jaggery Processing Plant at Punjab Agricultural University (PAU) in Ludhiana has been established recently which aims to address post-harvest losses, enhance agro-processing and value addition, and improve rural livelihoods by supporting farmers. The department has been instrumental in establishment of Agro Processing complexes across Punjab and is being published on ICAR website for popularization across the nation. Developed and commercialized various post-harvest machineries i.e PAU Portable maize dryer, Horticultural Produce Washing Machine, Honey Heating-cum Filtration Unit, Turmeric Washing and Polishing Machine, Brick and Sand Store, Electric-cum-Battery Heated Uncapping Knife, Radial Honey Extractor, Aloevera Leaf Gel Extraction Machine, Pilot Scale Plant for Pectin Extraction for kinnow and mosambi waste (peel), Mechanically Ventilated Onion Storage Structure, PAU Protection Kit for Pulses.

3. The Department of Food and Nutrition has developed a range of REC-approved post-harvest technologies to enhance the nutritional quality, safety, and value of foods while supporting health and economic sustainability.

Key innovations include:

Beetroot Powder – A natural substitute for artificial food colors, enriching cakes, cookies, bread, and doughnuts with antioxidants and vibrant color.

Pumpkin Seed Flour – Can be added up to 30% in panjeeri, mathi, and cookies to boost protein, fiber, iron, zinc, carotenoids, and antioxidants.

UV-Treated Mushrooms – Button and oyster mushrooms exposed to UV rays show a significant increase in Vitamin D₂.

Wheatgrass Powder – Made from 7–10-day-old shoots using freeze or shade drying; an excellent superfood to enrich meals.

Mulberry Products – Six items (jam, chutney, crush, syrup, leather, dried mulberry) standardized with high antioxidant retention for up to four months.

Karonda-Based Products – Green karonda powder rich in vitamin C (41.62 mg/100g) and pink ripe powder high in anthocyanins (388.59 mg/100g).

Microgreens – Spinach, coriander, broccoli, and carrot harvested on day 10, preserved with microwave dehydration to retain β-carotene and vitamin C, offering a fresh way to boost antioxidant intake.

Fruit Varieties : Grain production in the Punjab is self-sufficient due to the prevalence of the wheat-rice cropping pattern, especially in Punjab and the surrounding states. Nevertheless, this area has severely degraded its natural resources due to the intense agricultural strategies. Fruit varieties play a pivotal role in crop diversification by improving resilience, sustainability, and profitability in farming systems, while also contributing to better nutrition and rural livelihoods. Diversification with multiple fruit varieties provides farmers with continuous income opportunities across seasons and shields them from price fluctuations. Growing multiple fruit varieties reduces the risk of total crop failure due to pests, diseases, or adverse weather, as different varieties respond differently to stresses. By cultivating early, mid, and late-maturing fruit varieties, farmers can stagger production, ensuring availability of fruits for longer periods and reducing market glut. More importantly, compared to cereal crops, established orchards give significantly more revenue per unit area. Fruit cultivation may significantly contribute to more profitability and nutritional security of the farmers and will be helpful in diversifying the varietal monoculture in fruit cultivation under Punjab conditions.

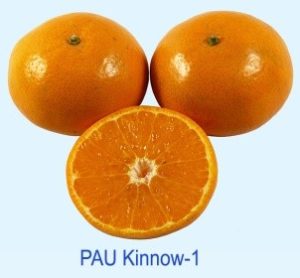

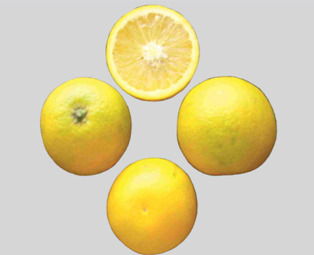

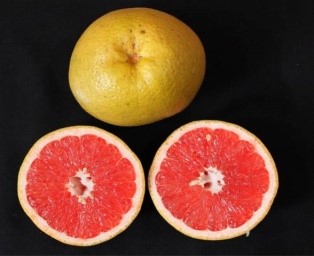

Over the last decades, the department has engaged in the collection, development and assessment of germplasm from a variety of crops, both within the country and abroad. With the release commercially seedless variety viz. ‘PAU Kinnow-1’, Punjab citrus growers will now have access to profitable markets in America and Europe. This variety is expected to enhance the citrus industry in Punjab, resulting in improved returns for the growers. Other notable varieties in citrus include Early Gold, Vaniglia Sanguigno and Flame grapefruit. In a similar vein, research initiatives were undertaken by PAU to recommend notable guava varieties suitable for commercial farming, such as Punjab Apple Guava, Punjab Safeda and Punjab Kiran. Additionally, other significant varieties recommended include Black Fig-I (fig), Chandler and Winter Dawn (strawberry), Anna, Dorsett Golden (apple), White Dragon 1 and Red Dragon 1 (dragon fruit), Kokan Bahadoli, Gomma Prianka (Jamun), Punjab Rasbhai 1, and Punjab Rasbhari 2 (Cape Gooseberry). The high demand for planting materials of these varieties among fruit growers reflecting their significance and adaptability under crop diversification programme in Punjab.

| S. No. | Crop | Variety | Varietal description | Photo |

| 1. | Citrus | PAU Kinnow 1 |

|

|

| Early Gold |

|

|

||

| Vaniglia Sanguigno |

|

|

||

| Flame Grapefruit |

|

|

||

| 2. | Guava | Punjab Apple Guava |

|

|

| Punjab Safeda |

|

|

||

| Punjab Kiran |

|

|

||

| 3. | Jamun | Goma Priyanka |

|

|

| Konkan Bahadoli |

|

|

||

| 4. | Apple | Dorsett Golden |

|

|

| Anna |

|

|

||

| 5. | Strawberry | Chandler |

|

|

| Winter Dawn |

|

|

||

| 6. | Dragon fruit | Red Dragon-1 |

|

|

| White Dragon-1 |

|

|

||

| 7. | Fig | Black Fig 1 |

|

|

| 8. | Cape gooseberry | Punjab Rasbhari 1 |

|

|

| Punjab Rasbhari 2 |

|

|

AGROFORESTRY : Agroforestry has huge potential in Punjab for diversification of agriculture, better profitability and sustainability of environment. Approximately, 1,30, 000 ha area is covered under agroforestry systems based on poplar, eucalyptus, Burma dek, etc.

| Variety | Clone Name | Year of Recommendation | Specification |

| Eucalyptus | PE-11 | 2022/ 293th REC Meeting | 15.61% volume index, 7.41% for tree height, 3.77% for DBH growth than existing commercial cultivated clone C-413 |

| Dek | Punjab Dek 1 & Punjab Dek 2 | 2021/ 286th REC meeting | Clear bole height (18.5 & 13.6 %), Straightness (21.3 & 19.6 %), per tree volume of Punjab Dek 1 & Punjab Dek 2 is 0.385 m3 and 0.284 m3 which is 163.5 % & 94.4% higher than the over mean of all general population. |

| Casuarina | IFGTB-CH-2 | 2025/307th REC meeting | The clone is superior for growth characteristics and stem biomass |

| Faculty of Electron Microscopy and Nanoscience Laboratory, PAU Ludhiana | |||

| Name and Designation | Local Address | Telephone/Mobile | |

| Dr. (Mrs) Anjali Sidhu Nanotechnologist (Chemistry) | 8360803103 | anjalisidhu@pau.edu | |

| Dr. Anu Kalia Assistant Professor Nanoscience, Incharge | H.No. 1814, SBS Nagar, Ludhiana | 9914620240 | kaliaanu@pau.edu |

| Dr. Gurkirat Kaur Assistant Professor Nanotechnology | H.No. 854/1, Street No.16/1, Punjab Mata Nagar, Pakhowal Road, Ludhiana | 9501134768 | gurkirat@pau.edu |

| Dr. Kiran Jeet Assistant Professor Nanotechnology | 243-E, BRS Nagar, Ludhiana | 9915066549 | kiranjeet@pau.edu |

| Dr. Mehra Singh Sidhu Assistant Professor (Nanotechnology (Physics)) | #766, Street 2L, Hira Bagh, Jagraon, Ludhiana – 142026 | 9779557712 | sidhums@pau.edu |

| Dr. Nitish Dhingra Assistant Professor (Nanotechnology Physics) | H. No. 5686, St. No. 6, New Shiva Ji Nagar, Ludhiana | 9417815830 | nitishdhingra@pau.edu |

Food processing minimizes wastage by utilizing excess of the produce. Processing also increases shelf life of produce thereby ensuring that seasonality of some agricultural products can be reduced. Almost all food is processed in some way before it is eaten.

Food processing has certain objectives, such as:

In Punjab, primary processing of agricultural produce is quite important as it can be handled by the farmers themselves. This can result in enhancing farmers’ income, creation of employment opportunities in rural areas, reduction in post-harvest losses and access to quality food products being used daily in our houses.

Agro-processing is a necessary intervention where the farm produce cannot be consumed in its natural format. Primary processing converts the agricultural produce into its eatable form. Agro- processing infrastructure is key to bringing much agricultural output to markets thus providing another avenue to farmers to monetize their production. The agro-processing industry also helps in minimizing food loss by utilizing the produce for its value addition and income generation.

Keeping in mind above justification, a modern agro processing complex (APC) has been installed near Biotechnology Center, PAU Ludhiana. The main objectives of this APC are

The APC is having following modern machinery for primary processing of durable crops

Cleaning, grading and packaging of pulses

This set up has the following machines

This unit helps the farmers to add value to their raw produce by innovative processing and packaging machinery. The capacity of this unit is 100 kg/hr

Mini Dal Mill

This machine is used for making dal (split and dehusked) from moong beans, black chana and other pulses after providing some pretreatments. The capacity of the machine is 100 kg/hr. The colour sorter can be used for separation of dark coloured grains in pulses.

Mini Rice Mill

This rice mill can be used for processing the PAU premium basmati rice varieties such as Pusa basmati 1121 and Punjab Basmati 7 in very efficient and effective way. This unit has the following machines

The capacity of this machine is 500 kg/ hr. (Figure 3)

Cold/ hydraulic oil press

This machine is quite useful in extraction of oil from oil seed crops such as mustard, canola, groundnut and sunflower etc. under low temperature and high pressure conditions. These conditions help in maintain the quality of oil as well as oil seed cake. Most of the oil present in the oilseed can be extracted and a very small amount of oil remains in the deoiled material. There is no need to filter the oil obtained from this unit. The capacity of this machine is about 25 kg/hr. (Figure 4)

Wheat Flour mill

Having a capacity of about 300 kg/ hr, this unit grinds wheat at low RPM (about 200-300 rpm) resulting in good quality wheat flour (atta). (Figure 5)

This unit is having following machines

Animal/ poultry feed mill plant

The byproducts obtained cold oil press, mini rice mil, atta chakki and dal mill can be effectively used for making animal/ poultry feed. For this, The APC also houses a small (100 kg/hr) animal feed mill plant.

Apart from these, the complex is having state of the art packaging machinery for grains, powder and liquid materials

In this agro processing complex, the premium varieties of PAU such as Punjab PBW 1 Chapatti (wheat), Punjab Basmati 7 (basmati paddy), GSC 7, RLC 3 (canola oil seeds) etc. are processed for their popularization. (Figure 6)

Grain Storage System (Grain Silos)

To avoid the losses of food grains in traditional bag storage system, the bulk storage system has been installed in the APC compound. The bulk storage system of silo is quite effective in long term storage of food grains

This storage system includes the followings

Two grain storage silos (50 quintals capacity, each)

Conveying system consisting of bucket elevator and screw conveyor

Electric drying system

Aeration system

The installed silos can be effectively used for storage of wheat, maize, pulses and oilseeds for a long time. The grains to be stored should be thoroughly cleaned and dried below the safe storage limit of moisture content. (Figure 7)

Type of Grains | Safe storage moisture content |

Wheat | <12% |

Pulses and oilseeds | <10 % |

Maize | <13 % |

Auto-steering system is a GNSS-based guidance technology to maintain precise steering control, thereby reducing errors caused by manual steering. Auto-steering system helps in operating tractor-mounted implements along a predefined path with enhanced accuracy, reducing missed areas, overlaps, and the number of passes required during field operations. The average overlapped area (in lines), when the tractor was operated with manual steering, was 3-12% for different tillage and seeding machines, whereas with auto-steering system, the average overlapped area was about 1%. Similarly manual steering control, while operating these machines, resulted in missed area (in lines) of 2.0-7.0%, whereas the missed area was less than 1% when the auto-steering system was used to operate these machines. The auto-steering system led to precise work minimal wastage of input resources, enhanced working hours, and improved productivity. The operator’s fatigue also reduced, allowing him to focus on implement management. Further, parallel sowing lines facilitate subsequent mechanical intercultural and harvesting operations.

The PAU manually operated seeder for vegetable crops is a machine for direct sowing of vegetable crops like peas, radish, turnip, spinach, gram, fenugreek, okra, mustard, millets etc. The seeding unit of the machine comprised a shoe-type furrow opener, cylindrical seed box, and revolving plate-type metering mechanism. The number of seeding units and spacing between them i.e. row to row spacing is adjustable. Different seed metering plates can be used for accommodating diverse seed types and achieve different plant-to-plant spacing. The field capacity of the machine is 0.15-0.28 acres/h. Depending upon type of crop, there is saving in cost of operation by 48-82% and saving in labour by 55-85% as compared to conventional pora method or manual seeding by hand (choka/ chundi method). Ergonomically, machine is easy to operate. The machine could be very useful for small farmers.

The tractor-operated Turf Manager is a PTO-driven machine designed for simultaneously cutting and collecting the grass. The machine consists of high performance rotor mechanism with multiple flail blades that trim grass and plant residues while generating airflow to transport the material into a rear mounted collection hopper. The field capacity of the PAU turf manager ranges from 0.2 to 0.3 ha/h. The fuel consumption varied from 12 to 20 l/ha, depending on intensity of grass in the field. The quantity of grass collected during evaluation of machine varied from 0.3 to 0.7 t/h. The collecting hopper can hold grass up to 200 kg. The integrated hydraulic system allows easy dumping of the collected material into the field.

In-situ residue incorporation of cotton stalks and wheat sowing as well as in-situ incorporation of wheat residue with Super Seeder, resulted in higher seed cotton yield, wheat grain yield and improved soil physical parameters. Soil infiltration rate improved from 2.75 mm/h to 3.44 mm/h. Also soil bulk density reduced from 1.58 gm/cm3 to 1.46 g/cm3.

This machine can sow mat type nursery which is sufficient for transplantation in 150-180 acres paddy field area per day. There is a cost saving of 64-67 % and labour saving of 92-94 % with Tractor operated mat type nursery seeder as compared to conventional manual method of mat type nursery sowing. The machine can help in timely sowing and healthy mat type paddy nursery, thereby, can help in large scale adoption of mechanical transplantation of paddy in the state.

A pneumatic planter uses air pressure to precisely place seeds in the soil. It utilizes either vacuum or positive air pressure to control seed flow, ensuring accurate spacing and depth, which leads to improved germination and higher yields. It drops one seed at a time. There was found no missing/doubling and results in the saving of costly seed. No Damage to the seed was observed during the sowing operation.

A pneumatic planter uses air pressure to precisely place seeds in the soil. It utilizes either vacuum or positive air pressure to control seed flow, ensuring accurate spacing and depth, which leads to improved germination and higher yields. It drops one seed at a time. There was found no missing/doubling and results in the saving of costly seed. No Damage to the seed was observed during the sowing operation.

PAU Surface Seeder comprises of straw cutter-cum-spreader fitted with seed and fertilizer box attachment. This machine can be easily operated by a 40 hp tractor or above. It is a low-cost machine that does uniform application of wheat seed & and basal fertilizer along with cutting & and spreading of paddy straw in a single operation. It is followed by irrigation for initiating the germination of wheat.

PAU Smart Seeder manages the paddy straw by partial incorporation in a narrow band and retains the remaining straw as surface mulch. PAU Smart Seeder places wheat seeds in a well-tilled narrow band of soil and covers the seed rows with soil, using furrow closing rollers. Tillage in seed rows and furrow closing rollers enhances the soil seed contact and conserves furrow moisture, which results in early and uniform wheat establishment compared to Super Seeder and Happy Seeder. PAU Smart seeder can be operated with a 45 or above hp tractor. The field capacity of the machine is 0.8-1.0 acre/h and the fuel consumption of the machine is 5.0-5.5 l/acre.

It is a tractor mounted machine for direct sowing of wheat in combine harvested paddy field. The machine is a combination of Roto broadcaster (Roto seed drill) and disc type seeding attachment. The machine consisted of a straw managing rotor for incorporation of paddy straw and a seeding unit for sowing wheat directly after combine harvesting. Seed and fertilizer tubes are opened at the rear of the discs. The furrow opener discs are powered. The shape of the blade is C-J type. The machine is operated by a 55 hp or above tractor. The field capacity of the machine is 0.22-0.27 ha/h with fuel consumption of 8-9 l/h.

Happy Seeder is used for sowing of wheat directly into the combine-harvested paddy

fields. It is a tractor PTO driven machine which can be operated by 45 HP or above tractor and can cover 6-8 acres/day. Happy seeder consists of a rotor for managing the paddy residues and a zero till drill for sowing of wheat. Flail-type blades are mounted on the straw management rotor, which cuts (hits/shears) the standing stubble/ loose straw coming in front of the sowing tine and cleans each tine for proper placement of seed in the soil. The loose stubble should be evenly spread.

A remotely controlled 2-wheel paddy transplanter was recommended for transplanting mat type nursery. The labour requirement for machine transplanting was reduced by 40%; the effective field capacity of the machine was increased by 10-11% and a net profit increase of 14.25% as compared to the conventional walk-behind paddy transplanter. The physical workload of the operator is also reduced resulting in increased work efficiency with the comfort and safety of the operator without entering in puddled field. The initial cost of the machine with the developed system has been increased up to 28%.

For spraying, a hexacopter drone fitted with a standard/extended flat fan nozzle or anti-drift/air induction nozzles can be used for spraying. The drone can be operated at a forward speed of 2.0-3.0 m/s and height of 2-3 m from the top of the crop and a pressure of 1.38 kg/cm2. Drone/UAV can be used for spraying in all crops especially good for tall crops at all the growth stages of the crops. A certified and trained pilot is required or mandatory for the operation of UAVs/drones in the fields. The total cost of the operation of a drone for spraying will be Rs. 889.7/h or Rs 296.6/acre.

This sprayer has three types of spraying arrangements, namely auto-rotate gun, boom type and drop-up type nozzles, which were operated by a single pump. The pump can be operated at 800 rpm to develop the desired pressure up to 35 kg/cm2. Boom and drop-up nozzle mechanism consists of 14 nozzles on the boom and 13 drop-up nozzles (Make: Teejet) mounted on a foldable 9.8 m wide boom with 67.5 cm nozzle spacing. Boom nozzles were used to spray on the top side of the plant canopy, and other drop-up nozzles were used to spray inside the crop canopy up to 65-75 cm below the boom and within the row or the underside of the leaf through an adjustable drop-up arrangement of the nozzle to target whitefly residing locations. The height of the boom can be adjusted in the range of 30-250 cm according to the crop height.

PUNJAB AGRICULTURAL UNIVERSITY PUMP TESTING CENTRE

The Pump Testing Centre at Punjab Agricultural University (PAU), Ludhiana, is a state-of-the-art facility established to scientifically evaluate the performance of agricultural and irrigation pumps. Accredited by the National Accreditation Board for Testing and Calibration Laboratories (NABL), it operates in compliance with ISO/IEC 17025 standards, ensuring that all tests are conducted with high precision, traceability, and reliability. The centre is equipped with advanced instrumentation to measure discharge, head, input power, pump efficiency, and overall performance curves for submersible pumps, in accordance with BIS specifications. NABL accreditation signifies that the test results are nationally and internationally recognized, which benefits manufacturers in quality assurance, farmers in selecting energy-efficient pumps, and researchers in developing improved irrigation technologies. By providing unbiased, third-party testing, the PAU Pump Testing Centre plays a crucial role in promoting water and energy conservation in Punjab’s agriculture sector.